Current location: Home»CP Mosaic News » News center » Industrinal news » The process of making Coconut shell mosaic

Recommended Products

- glass mosaic NGL036

- Item:NGL036 Sheet size:300*300mm Chip size:23*23mm Thickness:4/6/8mm Material:glass MOQ:36 square meters

Top articles

- Analysis of the thickness and advantages and disadvantages of glass mosaic

- Do you know what is the mosaic tile?

- The Features of Mosaic Tile

- Electroplating mosaic with rich color and multi change patterns

- Crystal Glass Mosaic Features

- What are the characteristics of glazed metal mosaic?

- Application of glass mosaic in bathroom space

- Stone Mosaic could be decorated to which places?

- What kind of mosaic tile should be used for home ground decoration?

- Mosaic Tile Installation

Latest articles

- Make your swimming pool specially

- congratulate you with international woman day!

- Analysis of the thickness and advantages and disadvantages of glass mosaic

- glow in dark mosaic tile

- Do you know what is the mosaic tile?

- The Features of Mosaic Tile

- Provide with Fashion trend low cost cystal glass mossaic from CP Mosaic manufacturer

- New inkjet mosaic and glass tile

- Electroplating mosaic with rich color and multi change patterns

- Working instructions of mosaic

Your browsing history

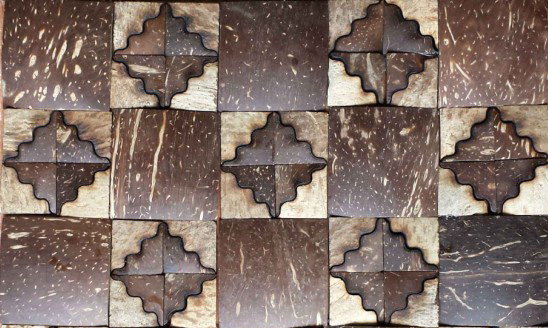

The process of making Coconut shell mosaic

Coconut shell mosaic (coconut parquet board) after the Hainan natural coconut from beautiful mature hard shell. Its shell has a dense fibrous layer, hard wear and pattern drift ,, has strong corrosion resistance.

Coconut shell mosaic process is in accordance with the choice of raw materials, grinding, slicing, polishing, re-selection, parquet, patches, and other naturally dried and worked closely interconnected process carefully made of.

Coconut shell mosaic process is as follows:

1. Selection: Choose ripe coconut, which is the outer layer of loose skin removed, it can be rendered texture dense, hard shell.

2, Grinding: Empty coconut and copra coconut inside the coconut shell is placed in the sun to dry, dry. Manual grinding (surface) let it completely dry after polishing.

3, Slicing: coconut shell because of its original characteristics (irregular oval or circular) restrictions, to the finished product as a decorative material (such as brick), it must be coconut shell mosaic processing (manufacture) requirements cut into 1cm ~ 4cm between a variety of small coconut pieces.

4, SMD: coconut shell mosaic patch is a vital part of process, and therefore must be careful of every detail according to process requirements. The first is the selection, namely: the coir sheet forming screening again; followed paste, namely: the pattern of the design requirements, the coconut shell mosaic pieces and pasted shape.

5, Natural drying: good coconut paste parquet boards must not use baking, roasting and other methods to dry, but can only use natural air, drying methods. The coconut shell mosaic process is very important, and it can not take the slightest bit of a shortcut, as it will directly affect the quality and performance of the product.

So, beautiful, simple, personality, fashion coconut parquet board arose.

Coir parquet panels are made of pure natural ingredients, pure manual process, and thus created a natural, environmentally friendly, healthy quality, worthy of a "green" rookie decorative material.

Previous page:How to install Metal MosaicNext page: The application of Quintana Mosaic